-

01

01

Melt strength

control -

02

02

Foaming process tailored to the characteristics of crystalline resin

-

03

03

Elaborate Design of screw & die

-

04

04

Recipe tailored to raw material properties

-

05

05

Optimization of the foaming process

PET Foam Sheet Extrusion Line

Myung-il Foamtec’s innovative foaming extrusion technology is differentiating itself in the eco-friendly semi-crystalline polymer PET field,

and it showcases technology with a foaming ratio of up to 14 times and a thickness of 1 to 5 mm.

Specifications

| MODEL | TYPE | THROUGHPUT | WIDTH | THICKNESS | EXPANSION RATIO | SCREW DIAMETER | L/D | BLOWING AGENTS |

|---|---|---|---|---|---|---|---|---|

| PET | Tandem | 350~550 | 600~1200 | 1~5 | UP TO 14 | 150-180 | 32:1 | Hydro carbon & CO₂ |

PET foam material properties

PET

foam

Strength

Strength

Longer lifespan due to excellent oxygen barrier properties

Longer lifespan due to excellent oxygen barrier properties Low raw material cost

Low raw material cost

Microwave available

Microwave available Can be heated to 180°C

Can be heated to 180°C

Weakness

Weakness

Difficulty foaming

Difficulty foaming Requires special recipe for foaming

Requires special recipe for foaming

Raw materials need to be dried before use

Raw materials need to be dried before use Extrusion technology with advanced screw and die is required

Extrusion technology with advanced screw and die is required

Applications

FIELD 01

Packaging

- Food Package

- Cold & Hot Food package

- Cold & Hot Coffee cups

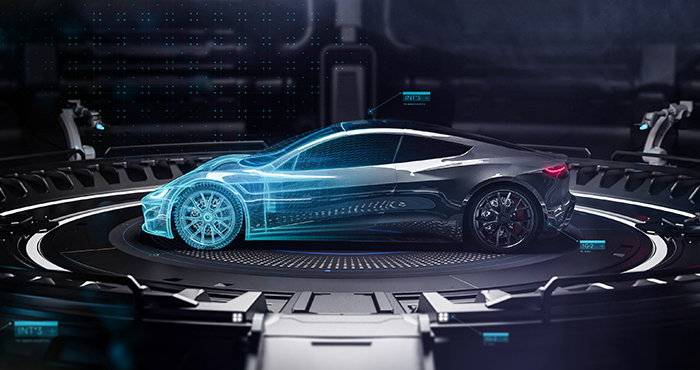

FIELD 02

Automotive industry

- Headliner

- Trunk liner

- Foam insulation under the hood

FIELD 03

Renewable energy

- Wind Generator