Myung-il Foamtech leading the market with differentiated technology

Based on more than 45 years of experience and innovative

and standardized technology,

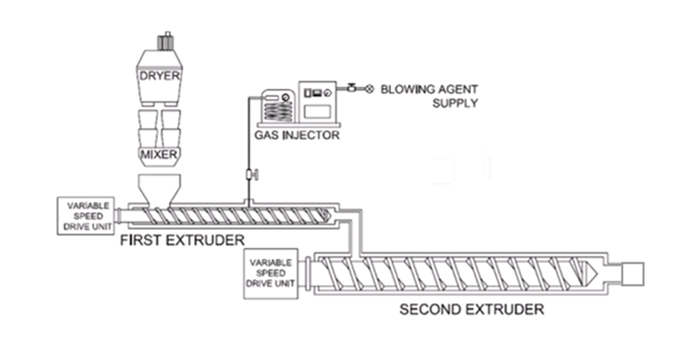

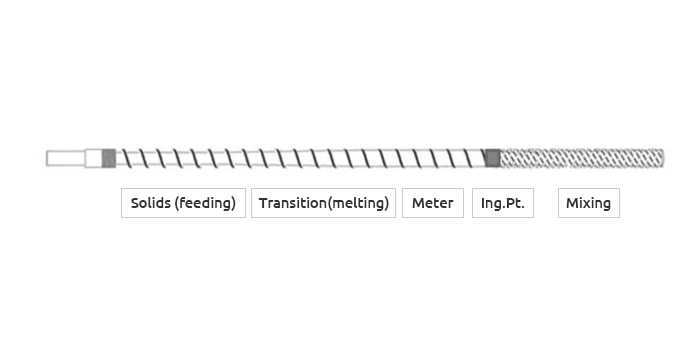

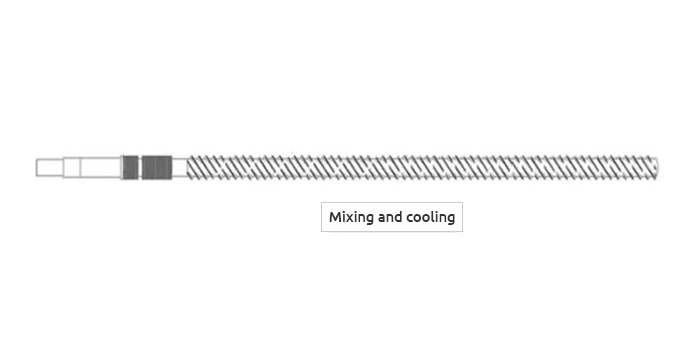

We are positioning as a leader in foam extrusion technology. Myung-il Foamtech is specialized in manufacturing not only PE, PS, XPS, but also eco-friendly PP, PLA, and PET extruders. It possesses outstanding technology and is leading the plastic foam extrusion technology in the global market.

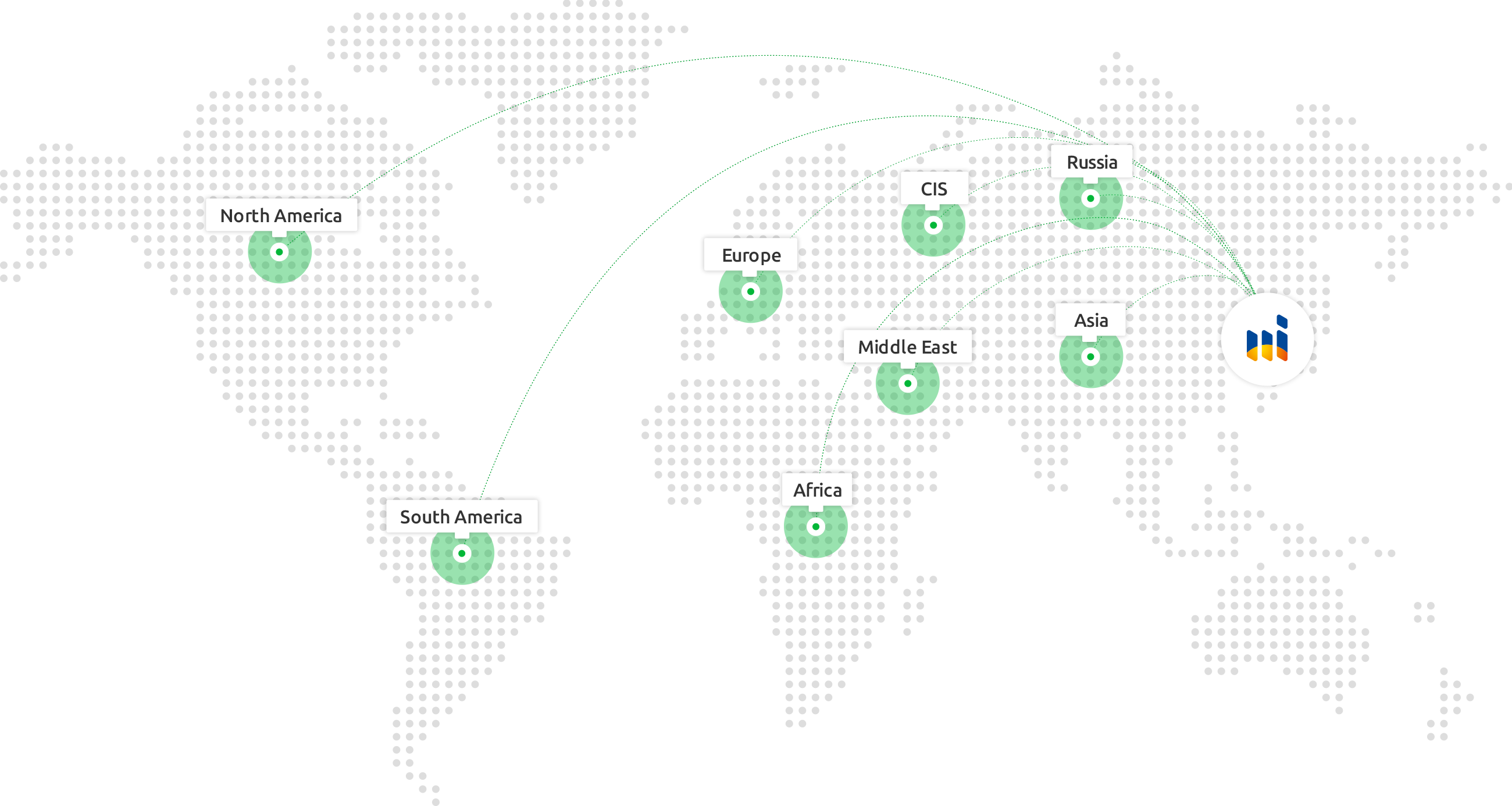

Our technology is used in many industries such as automobiles, packaging, and construction. Myung-il Foamtech was established in 1975 and has over 200 customers around the world. World-class manufacturers are using Myung-il Foamtech's machines.

Innovative foaming technology, such as the foam extrusion line for new materials and ideal material blending, has been studied through continuous R&D.

Myung-il Foam, a subsidiary, is the largest XPS foam producer in Korea and produces excellent quality foam boards. It is also recognized in the semi-fractured PF foam board market.

Myung-il Foamtec has grown into a company that can supply not only excellent machine lines, but also the mixing (prescription) technology of raw materials. In the future, Myung-il Foam Tech will continue to provide differentiated technology and We will grow as a partner that helps our customers develop.